Allread’s Solution for Container Damage Detection.

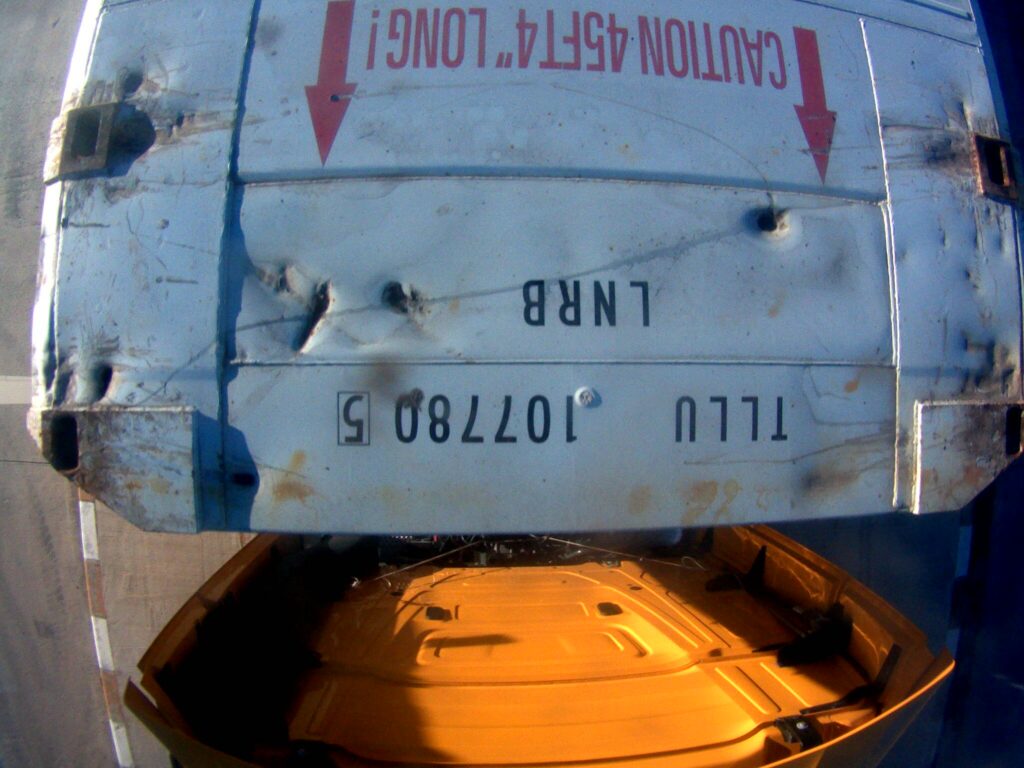

Containers get damaged. It happens all the time at terminals. But catching that damage early? That’s been the hard part. The stakes are high. A small crack in a container wall can ruin everything inside. Water gets in. Cargo spoils. Security gets compromised. When that happens, the costs pile up fast.

Why Container Inspection Is So Hard

Containers aren’t pristine museum pieces. They’re beat up from years of use. They come covered in rust, dirt, stickers, and old paint. Some are bright orange. Others are faded gray. Damage comes in all shapes and sizes too. A tiny scratch. A massive dent. A hairline crack that’s barely visible. Each type needs different handling. Traditional computer vision couldn’t handle this mess. Rule-based systems would flag every rust spot as damage. Or miss real cracks because they looked too much like normal wear. The variability was the killer.

The Problem with Manual Inspections

Global trade depends on these container hubs. When something goes wrong, the effects spread everywhere. Supply chains break down. Costs go up. Deliveries get delayed. Manual checks slow everything down. Inspectors can only look at so many containers per day. And people make mistakes. They miss things when they’re tired. They see damage that isn’t there when lighting is poor. This is why automation matters. Not because it’s trendy. Because it solves real problems that terminal operators face every day.

The Technical Breakthrough

Building a system that actually works took years of research. Allread partnered with the Computer Vision Center in Catalonia through the CERVERA project IVAM, funded by the CDTI agency. The team had to solve several problems at once. The system needed to tell the difference between real damage and normal container wear. It had to work in different lighting conditions. And it had to be fast enough for real-time use.

Visual language models made the breakthrough possible. The system combines two types of AI technology. Vision transformers look at images like humans do, but process them faster. Large language models understand what they’re seeing. Put them together with traditional computer vision networks, and you get something pretty useful. The real challenge wasn’t building the AI. It was making it work in the real world. Containers come in different shapes, colors, and lighting conditions. Damage can look different depending on the angle or weather. The system needed to handle all of this while staying accurate.

The result is a lightweight model that can spot and classify container damage. It doesn’t just say “damaged” or “not damaged.” It can tell you what kind of damage and how serious it might be.

How It Works

Containers move through the terminal on their normal path. Cameras capture images as they pass by. The AI system analyses each container in real time. When it spots potential damage, it flags the container for closer inspection. No more random checks. No more hoping inspectors catch everything important. The system learns from each inspection. It gets better at telling real damage from false alarms. Terminal operators get objective data they can trust.

What This Means for Ports

Faster inspections mean higher throughput. Fewer missed problems mean lower costs down the line. More consistent results mean better planning. But the real benefit is risk reduction. Catching damage early prevents bigger problems later. Cargo stays safe. Security stays intact. The supply chain keeps moving. Human inspectors don’t disappear. They focus on the cases that actually need attention. The AI handles the routine screening. Everyone works more efficiently.

This technology isn’t theoretical anymore. Allread has built and tested the system. The results show it can work in real terminal port environments. Computer vision for container inspection makes terminal ports safer, faster, and more reliable.

Want to learn more about computer vision solutions for terminal port operations?

Get in touch with our team to discuss your specific inspection challenges.